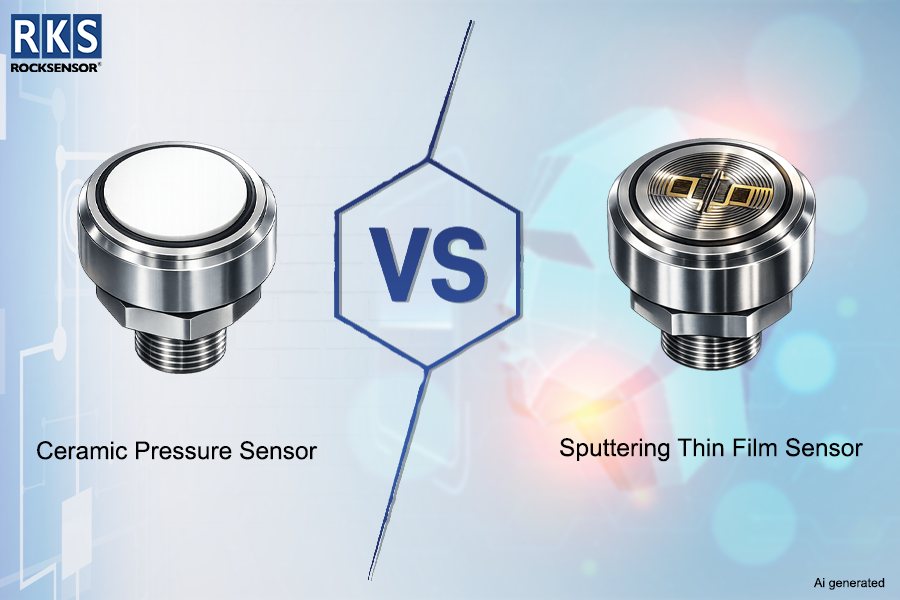

Choosing between a ceramic and a sputtering thin film pressure sensor usually depends on whether you prioritise cost and chemical resistance (Ceramic) or precision and long-term stability (Sputtering Thin Film).

While both measure pressure by detecting the deformation of a diaphragm, they differ significantly in construction, performance, and durability.

Comparison Overview

| Feature | Ceramic Pressure Sensor | Sputtering Thin Film Sensor |

|---|---|---|

| Manufacturing | Printed thick-film resistors on a ceramic base. | Metal resistors deposited via vacuum ion sputtering. |

| Bonding | Chemical/Glass frit bond (less stable). | Atomic-level bond (virtually permanent). |

| Accuracy | Good (\pm 0.5\% to 1.0\% FS). | Excellent (\pm 0.1\% to 0.25\% FS). |

| Durability | High chemical & corrosion resistance. | High resistance to vibration & shock. |

| Sealing | Requires O-rings (potential leak point). | All-welded (no O-rings, no leaks). |

| Cost | Generally lower / economical. | Higher due to the complex vacuum process. |

1. Ceramic Pressure Sensors

Most ceramic sensors use thick-film technology. Conductive and resistive pastes are silk-screened onto a ceramic diaphragm (usually Alumina, Al_2O_3) and then fired at high temperatures.

- How it Works: Pressure deforms the ceramic diaphragm, changing the resistance of the printed Wheatstone bridge.

- Best For: Harsh chemical environments. Because ceramic is nearly inert, it can handle aggressive fluids (acids, brackish water) that would corrode stainless steel.

- The “O-Ring” Weakness: Ceramic cannot be welded to metal. Therefore, these sensors must use an elastomer O-ring to seal the sensor to the housing. Over time, these seals can age, leak, or be attacked by chemicals.

2. Sputtering Thin Film Sensors

These sensors represent a “high-tech” approach. Instead of printing a paste, individual atoms of metal are “sputtered” onto a stainless steel diaphragm in a vacuum chamber.

- How it Works: This creates an atomic bond between the sensing film and the diaphragm. There are no glues or organic materials that can “creep” or degrade over time.

- Best For: High-performance industrial and automotive applications. They are famous for long-term stability; if you calibrate it today, it will likely still be accurate years later.

- Extreme Robustness: Because the diaphragm is typically stainless steel and can be laser-welded to the sensor body, there are no O-rings. This makes them “leak-proof” and highly resistant to intense vibration or pressure spikes.

Which one should you choose?

- Choose Ceramic if: You are on a budget, or you are measuring “dirty” or highly corrosive liquids that would eat through stainless steel.

- Choose Sputtering Thin Film if: You need “set and forget” reliability, high accuracy, or if the sensor will be subjected to heavy vibration (like on an engine block) or frequent pressure shocks (hydraulic systems).

Looking for accurate and reliable process measurement instruments?

Explore Rocksensor’s complete range of Pressure, Flow, Level & Temperature transmitters.

Download datasheets | Get a quote | Enquire today