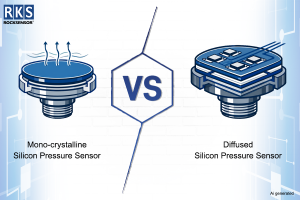

While both “Glass Micro Melt” (often called Micro-fused) and Silicon-Silicon (often called Silicon-on-Silicon) chips are MEMS-based technologies, they differ fundamentally in how the silicon sensing element is attached to the body of the sensor.

The choice between them usually comes down to a trade-off between ruggedness for harsh mechanical environments (Micro-fused) vs. high precision/miniaturisation (Silicon-Silicon).

1. Glass Micro Melt (Micro-fused) Sensors

In this technology, silicon strain gauges are bonded to a stainless steel diaphragm using a glass frit (high-temperature glass powder) that is melted at high temperatures (sintered).

- Construction: Small silicon “islands” are essentially glued to a metal diaphragm with a thin layer of glass.

- Key Advantage: It combines the high sensitivity of silicon with the mechanical strength of stainless steel. Because the glass bond is inorganic, it doesn’t “creep” or age like organic adhesives/glues.

- Durability: Excellent for high-pressure applications, heavy vibration, and hydraulic shock. Since the media (fluid) only touches the stainless steel diaphragm, it is very robust.

- Limitation: It is slightly less accurate than pure silicon-silicon chips because the glass layer and the metal diaphragm have different thermal expansion rates, which can introduce small errors.

2. Silicon-Silicon (Silicon-on-Silicon) Sensors

These sensors use fusion bonding or anodic bonding to join two silicon pieces (or silicon to a silicon-dioxide/SOI layer) directly at the atomic level.

- Construction: The entire sensing structure—the diaphragm and the frame—is made of silicon. There is often no intermediate material like glass or metal in the active sensing area.

- Key Advantage: Absolute Stability. Because the entire structure is the same material, there is no “thermal mismatch.” If the temperature changes, the whole chip expands and contracts at the exact same rate.

- Precision: These offer the highest possible accuracy and long-term stability. They are the gold standard for low-pressure measurements (like medical ventilators or cleanroom monitoring).

- Limitation: They are more fragile. Because the diaphragm is made of brittle silicon, they can be easily destroyed by pressure spikes or “water hammer” effects in hydraulic systems.

Comparison Summary

| Feature | Glass Micro Melt (Micro-fused) | Silicon-Silicon (All-Silicon) |

|---|---|---|

| Material | Silicon on Stainless Steel (via Glass) | Silicon on Silicon (Molecular bond) |

| Media Contact | Stainless Steel (very durable) | Often requires oil filling/isolation |

| Pressure Range | High (up to 10,000+ psi) | Low to Medium (highly sensitive) |

| Accuracy | Good (\pm 0.25\% to 0.5\%) | Best (\pm 0.05\% to 0.1\%) |

| Common Use | Hydraulics, Off-road vehicles, Industrial | Medical, Aerospace, Lab equipment |

Looking for accurate and reliable process measurement instruments?

Explore Rocksensor’s complete range of Pressure, Flow, Level & Temperature transmitters.

Download datasheets | Get a quote | Enquire today