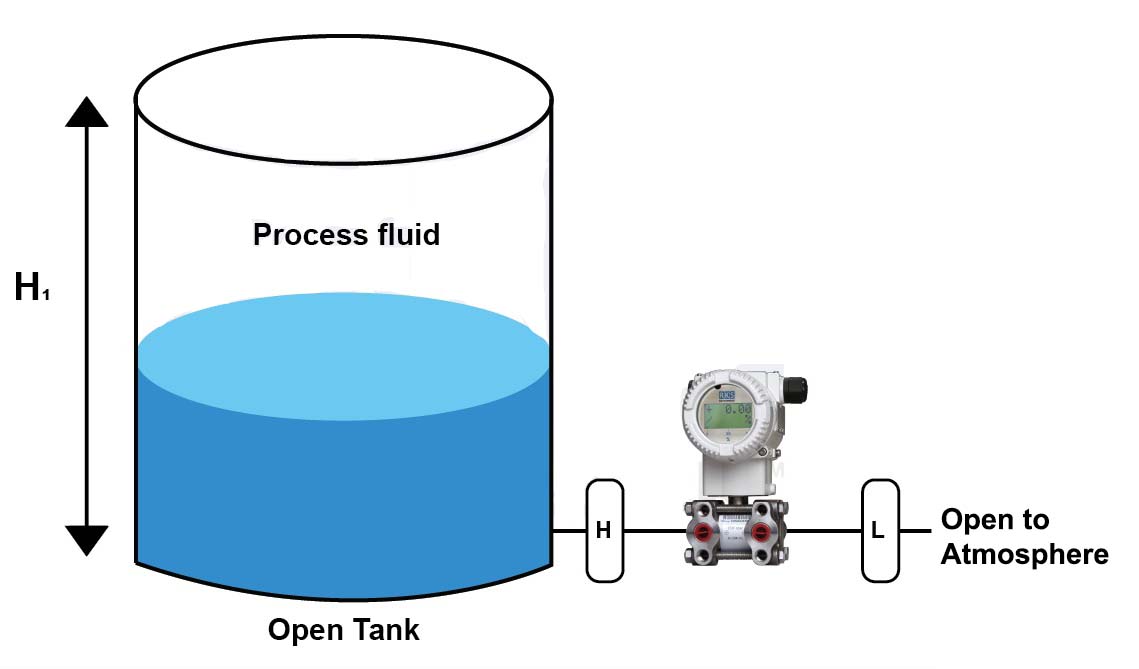

A. Open Tank Level Measurement

- Formula:

where:

P=H x SG

P = Pressure (mmWC)

H = Height of liquid column (mm)

SG= Specific Gravity of the liquid

- Example Calculation:

Suppose H1 is equal to 10m.

- At LRV (Lower Range Value): Height = 0 mm → Pressure = 0 mmWC

- At URV (Upper Range Value): Height = 10,000 mm (10 m) with SG = 1 → Pressure = 10,000 mmWC

- DPT Range: 0 to 10,000 mmWC

| Specific Gravity | Height | Pressure | Description |

| 1 | 10000mm | 10000mmWC | water |

| 0.85 | 10000mm | 8500mmWC | Oil |

| 2 | 10000mm | 20000mmWC | Mercury |

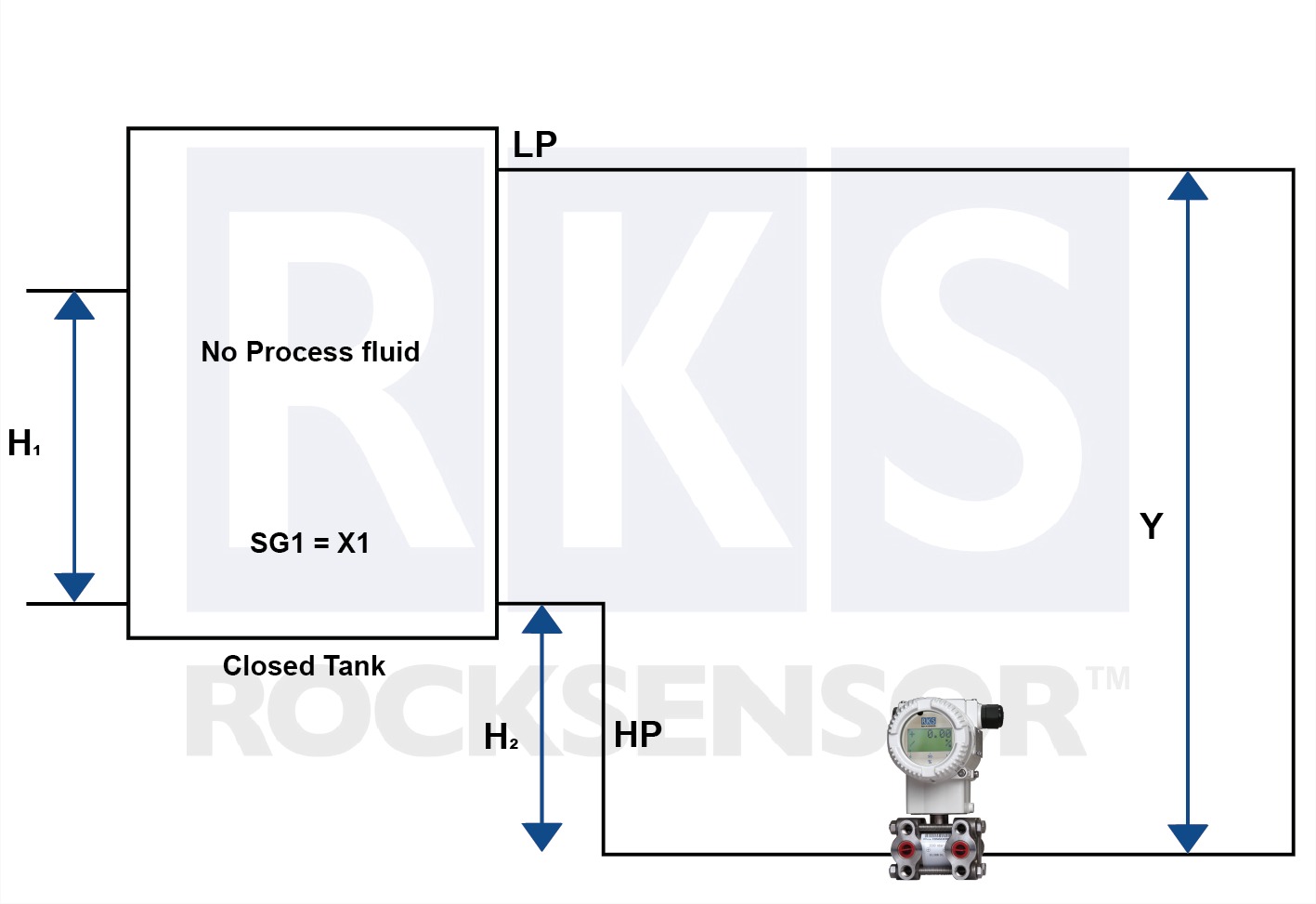

B. Closed Tank Level Measurement

- Formula:

DP= A- B

Where:

DP= Differential Pressure

A = Pressure at HP port (liquid column pressure)

B = Pressure at LP port (vapor space pressure)

At Zero Level (LRV)

Pressure acting on HP leg is P= H x SG

Suppose H2=1m & SG=1 then pressure at HP Port is 1000mmwc.

Pressure acting on LP Leg is P =H x SG

Here height will be H2+H1 and let SG be 1,H2=1,H1=10m

So it will be (H2+H1) x SG=11000mmwc

Finally DP=A-B

So LRV becomes negative, it will be -11000mmwc at LRV side

| H1(m) | H2(m) | SG | A(HP Port) | B(LP Port) | DP=A-B |

| 10 | 1 | 0.85 | 850mmWC | 9350mmWC | -8500mmWC |

| 10 | 1 | 1 | 1000mmWC | 11000mmWC | -10000mmWC |

| 10 | 1 | 2 | 2000mmWC | 22000mmWC | -20000mmWC |

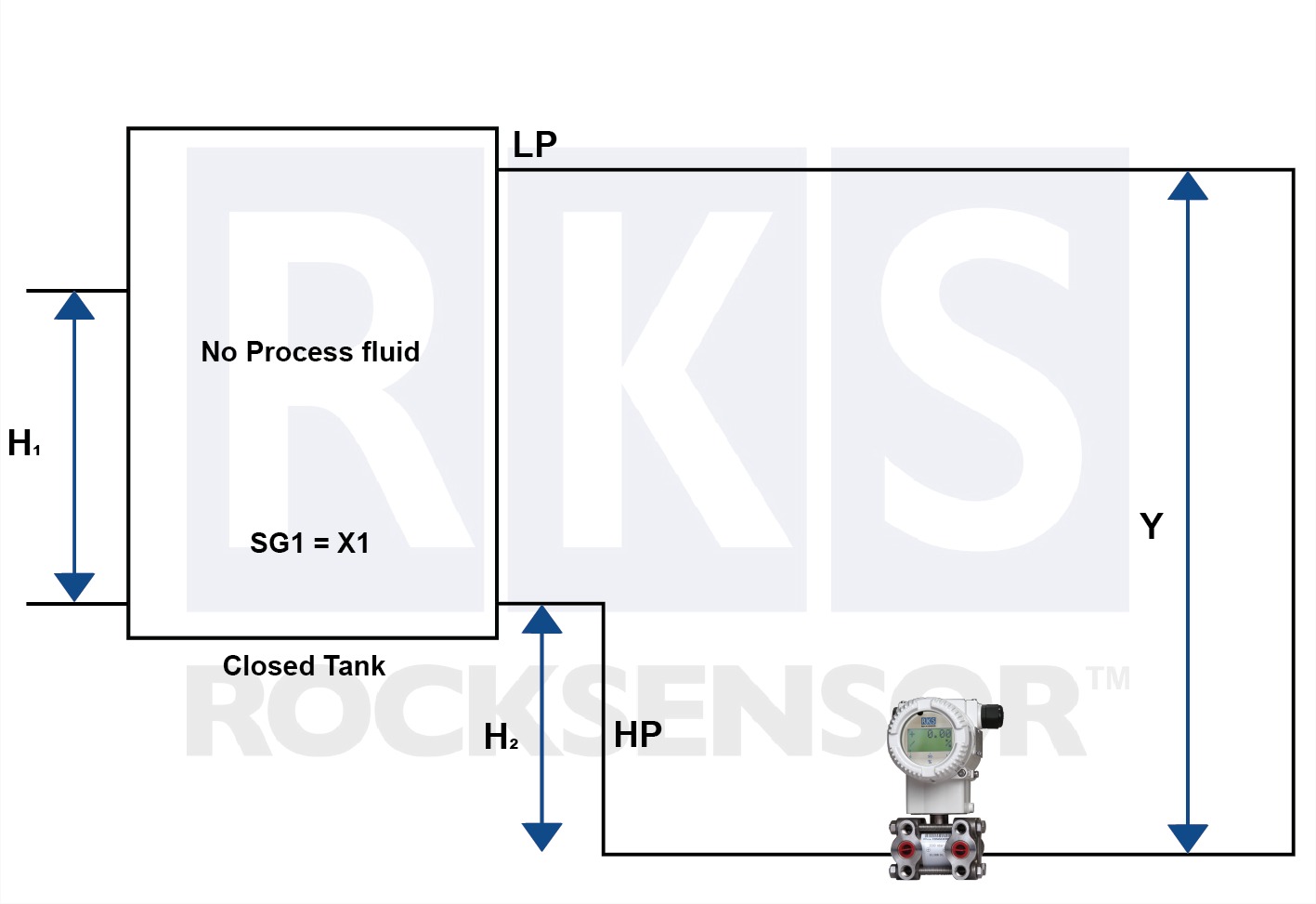

AT maximum level or 100% level

For URV it will be

DP= A- B

Where:

DP= Differential Pressure

A = Pressure at HP port (liquid column pressure)

B = Pressure at LP port (vapor space pressure)

A is P= H x SG

Suppose H2=1m,H1=10m , height is H2+H1 & SG=1

then pressure at HP Port is 11000mmwc

Same at LP port H is H2+H1 x SG

Then B pressure at LP Port is 11000mmwc

So if H2 is 1m and specific gravity is equal.

Pressure at HP leg and LP leg will be equal

Pressure difference will become zero & URV becomes Zero

Range is LRV to URV so range will be negative to zero that is -11000mmwc to 0

| H1(m) | H2(m) | SG | A(HP Port) | B(LP Port) | DP=A-B |

| 10 | 1 | 0.85 | 9350mmWC | 9350mmWC | 0mmWC |

| 10 | 1 | 1 | 11000mmWC | 11000mmWC | 0mmWC |

| 10 | 1 | 2 | 22000mmWC | 22000mmWC | 0mmWC |

Conclusion

- Correct installation of DPT based on fluid type ensures accurate measurement.

- Proper range setting using the height and specific gravity formula is essential for reliable operation.

- Using condensate traps, separators, and drain valves helps maintain measurement integrity in challenging conditions.

By following these guidelines, engineers can ensure accurate and stable level measurement using DPTs in various industrial applications.

Contact us today for a free consultation!

Email: info@rocksensor.in | www.rocksensor.in