Radar level sensors are becoming the primary option for level measurement in many industries. Few days back Rocksensor India has supplied 58 no. compact radar level transmitter for one of the smart city project in India.

Application

Challenges

Solutions

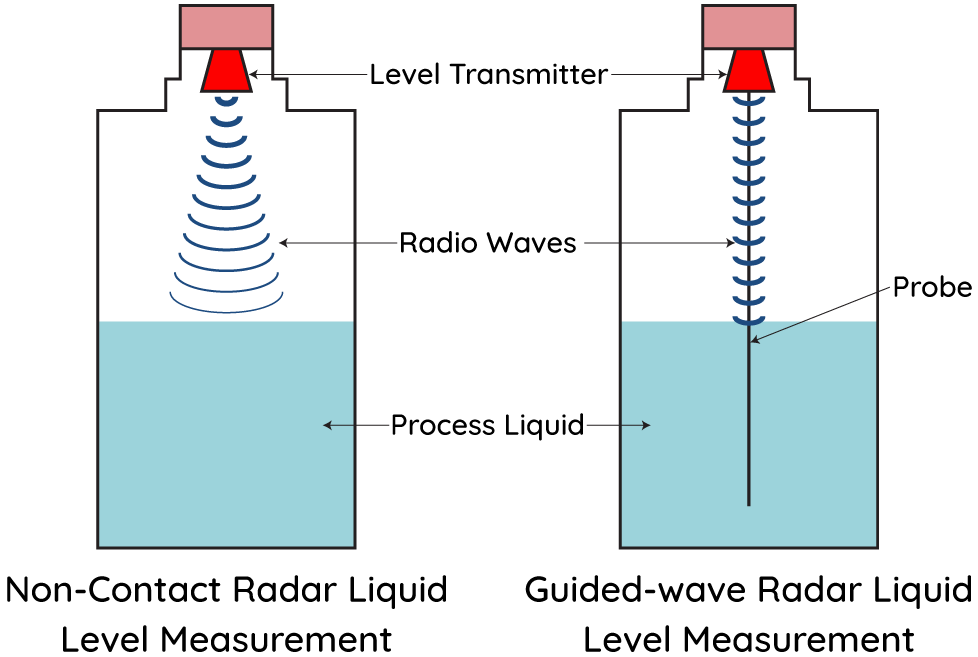

Radar level transmitters used for level measurements in different applications are of two types:

Contact Type Transmitter

Non-Contact Type Transmitter

Working Principle

Time of Flight

Frequency Modulated Continuous Wave

Key Industries

Mining Industry:

In the mining industry, these transmitters are used to check the depth or length of mines, as well as the level of the ore's surface. Due of frequency continuity, FMCW radar level transmitters are generally utilised here. When the only accessible medium is air, ultrasonic radar technology may be used.

Boiler Engineering:

Boilers are potentially hazardous equipment of machinery. Due to the extremely high water and stream temperatures, measuring fluid level is extremely challenging. In such cases guided wave radar level sensors are used. Their guided probes are immune to high temperatures and have no effect. Therefore, they are utilized in boiler applications as fuel level or fluid level indicators.

Aeronautics Industry:

In automobile industries, the fuel levels are frequently measured by using contact type level indicators. However, a fuel storage system is a little complex. Therefore, radar-level transmitters are used.

Paper and Pulp Industry:

In the paper and pulp industry level of slurry, water and storage tanks, can be measure using these level transmitters. As Guided probes can be utilised in chemical environments, therefore it is a suitable choice in paper and pulp industry.

Bore Digging Technology:

In the bore digging process, the level measurement devices are exposed to mud, slurry, and under-surface gases throughout the process. These level indicators are used to check surface levels in such instances.