What if one simple device could prevent your next million-dollar shutdown?

Picture this: It’s 3 AM, and your cement plant’s production line suddenly grinds to a halt. The kiln stops, workers scramble, and every minute of downtime costs thousands. The culprit? A blocked duct that could have been detected hours earlier.

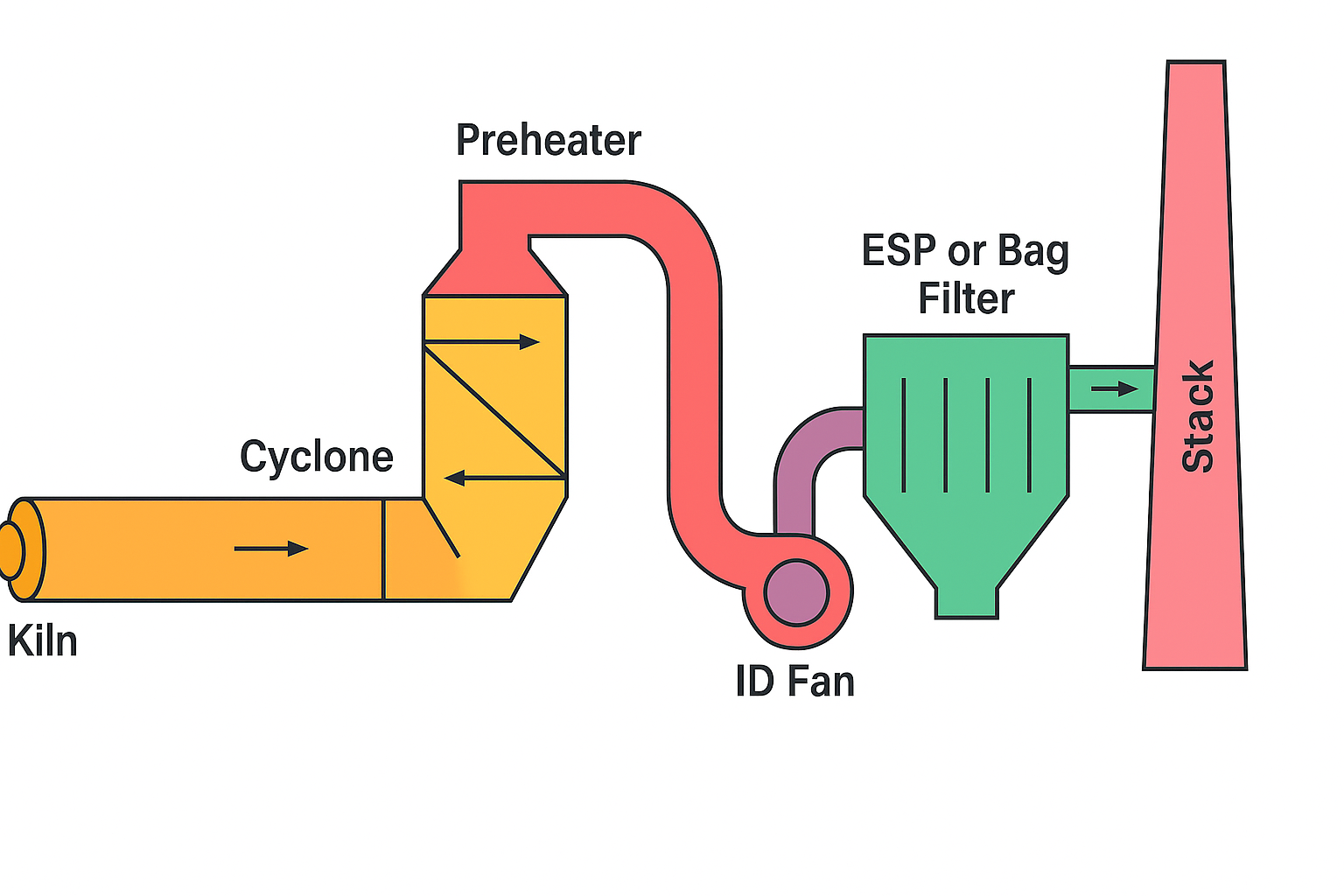

In cement manufacturing, your ducts are the circulatory system of your operation, transporting scorching hot flue gases through the critical pathway:

Kiln ➜ Preheater ➜ Cyclone ➜ Bag Filter/ESP ➜ ID Fan ➜ Stack.

But here’s what most plant managers don’t realise until it’s too late – when duct pressure monitoring fails, everything fails.

Operational Nightmares:

- Unexpected shutdowns that halt production

- Inefficient dust collection leading to compliance violations

- Energy waste from poorly optimised fan performance

- Equipment damage from undetected blockages and leaks

- Failed emission standards resulting in hefty fines

The Financial Impact: Even a single day of unplanned shutdown represents massive revenue loss, plus emergency repair costs and potential equipment damage. These unexpected downtime events can lead to millions in annual losses.

Why Traditional Monitoring Systems Fail You?

Most cement plants rely on outdated pressure monitoring that:

- Lacks stability for harsh industrial environments

- Can’t handle extreme pressure ranges (0-100 Pa to 3 MPa)

- Fails during overload conditions when you need them most

- Requires frequent recalibration, increasing maintenance costs

- Provides inaccurate readings over time

The Solution: RP1001 Differential Pressure Transmitter

Built Specifically for Cement Plant Realities

The RP1001 isn’t just another pressure transmitter – it’s engineered for the brutal conditions of cement operations.

Extreme Durability Features:

- High Stability Silicon Sensor – Designed for industrial challenges

- Wide Range Capability – Handles 0-100 Pa to 3 MPa coverage

- Overload Protection – Excellent performance during pressure spikes

- Long-term Reliability – ±0.15% stability over 10 years

- Safety Certified – ATEX, CE, and SIL compliant for the strictest regulations

Strategic Installation Points That Maximise Protection

Transform monitoring at these critical locations:

- Kiln Exhaust Ducts – Catch problems before they affect your entire line

- Bag Filter Inlet/Outlet – Monitor filter condition and prevent failures

- ESP Ducts – Ensure optimal electrostatic precipitator performance

- ID/FD Fan Monitoring – Improve performance and lower energy use

- Cooler Air Ducts – Maintain proper cooling system airflow

Key Benefits: Immediate Impact on Your Bottom Line

Prevent Costly Shutdowns

Early detection of blockages, leaks, and abnormal conditions means you fix problems before they stop production.

Massive Energy Savings

Optimised fan performance reduces energy consumption by 15-20%, resulting in significant electricity cost savings.

Compliance Confidence

Meet emission standards consistently with reliable pressure data that ensures proper dust collection and gas flow.

Maintenance Efficiency

Predictive maintenance based on accurate pressure trends reduces emergency repairs and extends equipment life.

Proven Results

Plants using proper duct pressure monitoring experience:

- Significant reduction in unexpected shutdowns

- Improved energy efficiency through optimised operations

- Better compliance with emission standards

- Lower maintenance costs through early problem detection

Don’t Let Poor Monitoring Be Your Plant’s Weak Point

Every day without proper duct pressure monitoring is another day you’re risking:

- Unexpected production halts

- Compliance violations

- Energy waste

- Equipment damage

Ready to transform your plant’s monitoring capabilities?

Contact our technical team today for a thorough review of your application and discover the potential savings in your operation. Don’t wait for the next unexpected shutdown – take control of your plant’s performance today.

Transform your cement plant’s efficiency with advanced pressure monitoring solutions that deliver real results.